Instytut z ENERGIĄ!

Przewaga w biznesie

dzięki wsparciu nauki

Sieć Badawcza Łukasiewicz przedstawi Ci rozwiązanie badawczo-rozwojowe.

doświadczenia

badawczych

biznesowych

Co nowego u nas?

Warsztaty dotyczące technologii SMR

Za nami dwudniowe (10-11 października) warsztaty dotyczące modułowych reaktorów jądrowych (SMR), które zorganizowane zostały w Sieci Badawczej Łukasiewicz. Był to dla wszystkich efektywnie spędzony czas.

kim jesteśmy?

Łukasiewicz to

Jedna z największych sieci badawczych w Europie składająca się z 22 instytutów a w nich 4500 naukowców i inżynierów, którzy tworzą innowacyjne rozwiązania, pozwalające uzyskać przewagę w biznesie.

- rozwiązujemy problemy

technologiczne - prowadzimy projekty

badawczo-rozwojowe - realizujemy badania

i certyfikacje

- pomagamy tworzyć

nowe produkty - sprawiamy, że technologie

działają lepiej,

są tańsze i efektywniejsze

nasza misja

Kreatywni ludzie, którzy z pasją tworzą innowacyjne rozwiązania dla rozwoju polskiej gospodarki.

nasza specjalność

Kierunki badań

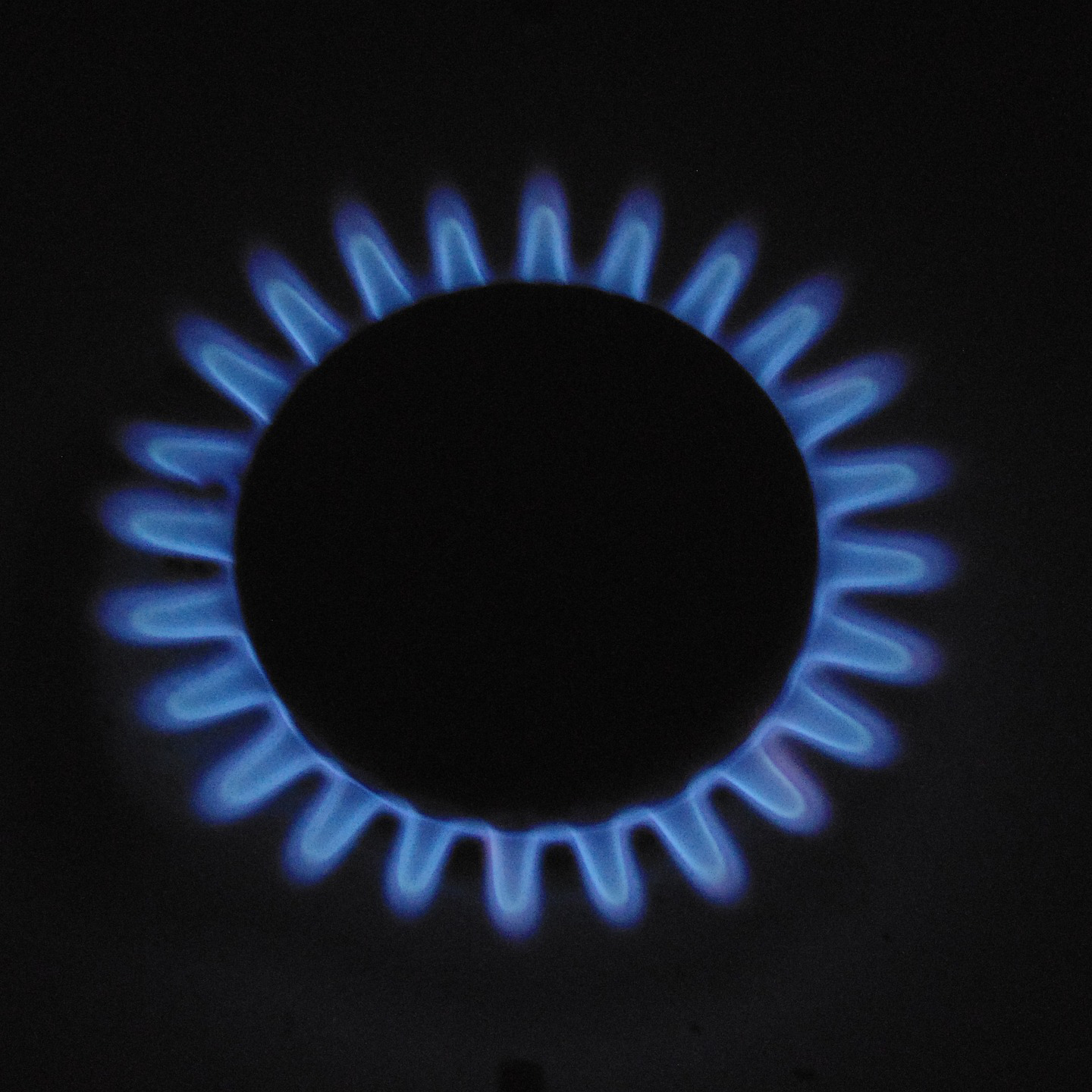

Przetwarzanie i Magazynowanie Energii

Centrum specjalizuje się w opracowywaniu nowych rozwiązań przetwornic energoelektronicznych i produktów na nich opartych oraz prowadzi jednostkową lub małoseryjną produkcję na zamówienie opracowanych wyrobów.

Elektromobilność i Inteligentny Transport

Zajmujemy się szeroko pojętą elektromobilnością, opracowujemy komponenty systemów napędowych, integracją systemową wraz z opracowaniem systemów zarządzania przepływami energii, oprogramowaniem kontrolnym pojazdu na poziomie nisko i wysokonapięciowym oraz komunikacji, systemami zewnętrznymi wykorzystywanymi do obsługi codziennej pojazdu i pracami operacyjnymi.

Systemy Energetyczne

Specyfiką naszego obszaru jest aparatura rozdzielcza i łączeniowa, urządzenia wysokiego i niskiego napięcia prądu przemiennego i stałego, układy wielkoprądowe stosowane w przemyśle i energetyce oraz technologie wysokiego i niskiego napięcia prądu przemiennego i stałego.

Technologie Wodorowe

Centrum prowadzi prace badawczo-rozwojowe w zakresie wytwarzania, magazynowania i przetwarzania wodoru, w szczególności w obszarze zbiorników wodoru gazowego oraz innowacyjnych materiałów elektrodowych dla elektrolizerów i ogniw paliwowych.

Materiały Elektrotechniczne

Obszary działalności obejmują opracowanie innowacyjnych materiałów oraz technologii dedykowanej branży elektrotechnicznej, a przede wszystkim podejmowane są tematy z zakresu recyklingu materiałów elektrotechnicznych, nowoczesnymi materiałami kompozytowymi i ceramicznymi, jak również technologiami wodorowymi.

Aparatura Elektroenergetyczna i Urządzenia Elektryczne

Laboratoria badawcze zajmują się badaniami typu, bezpieczeństwa, konstruktorskimi aparatury elektroenergetycznej i urządzeń elektrycznych wysokiego i niskiego napięcia, sprzętu ochronnego, źródeł światła, automatów do gier i narzędzi do prac pod napięciem wg wymagań norm oraz według specyfikacji klienta.

Korzyści

Co możesz z nami zyskać?

zespół ekspertów

wsparcie zespołu 4500

naukowców i inżynierów

zaplecze technologiczne

dostęp do blisko 4000 urządzeń aparatury badawczej i usług, w tym wiele unikalnych w skali kraju

czas

szybkie i darmowe opracowanie

propozycji rozwiązania technologicznego już w 15 dni roboczych

możliwość finansowania

identyfikujemy i pomagamy

w uzyskaniu dofinansowania

ze środków krajowych i zagranicznych

certyfikaty

oferujemy certyfikowane badania i usługi

krok po kroku

Rozwiązanie w 15 dni roboczych

W nie więcej niż 15 dni roboczych Łukasiewicz bezpłatnie proponuje rozwiązanie problemu technologicznego zgłoszonego przez przedsiębiorcę. Angażujemy w tym procesie kompetencje najlepszych naukowców i unikalną w skali kraju aparaturę badawczą.

Rzucenie wyzwania

Wystarczy, że wypełnisz prosty

FORMULARZ

Opracowujemy rozwiązanie Bezpłatnie

Analizujemy Wyzwanie i opracowujemy najlepsze propozycje rozwiązań

Spotkanie z klientem

Prezentujemy nasze najlepsze rozwiązania, a Ty decydujesz czy chcesz z nich skorzystać

Podpisanie umowy

Przechodzimy do realizacji projektu na wspólnie uzgodnionych warunkach

Sukcesy

3 lata Łukasiewicza

.

Zamówienia publiczne

Przetargi

Regulacje wewnętrzne Zamawiającego

Liderzy łukasiewicza

To oni odpowiedzą na Twoje Wyzwanie